WEMAC Beer brewing equipment micro brewery 100L 200L 300L 500L 1000L 2000L per batch ZXF

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

WEMAC beer brewing equipmentBeer brewing equipment micro brewerymicro brewery 100L 200L 300L100L 200L 300L 500L 1000L 2000L per batch Beer bre

If you're passionate about craft beer and dream of starting your own microbrewery, WEMAC has you covered. We offer a range of high-quality beer brewing equipment, perfect for small-scale brewing operations. Whether you're just getting started or looking to expand your current setup, WEMAC has options to suit your needs, with batch sizes ranging from 100 liters to 2000 liters.

Beer brewing equipment micro brewery 100L 200L 300L 500L 1000L 2000L per batch

1. 100L Microbrewery

Ideal for small-scale brewing experiments or pilot batches.

Perfect for testing new recipes and brewing small quantities of specialty beers.

Compact and cost-effective.

2. 200L Microbrewery

A step up from the 100L system, suitable for slightly larger production.

Great for catering to a local audience or experimenting with various beer styles.

Still compact, making it suitable for limited space.

3. 300L Microbrewery

Offers increased production capacity while maintaining versatility.

Suitable for small bars, restaurants, or expanding homebrewers.

Provides room for growth.

4. 500L Microbrewery

Perfect for serious homebrewers and small businesses.

Offers a higher production capacity to meet growing demand.

Allows for more extensive brewing experiments.

5. 1000L Microbrewery

A solid choice for microbreweries looking to cater to a broader audience.

Offers significant production capacity while maintaining quality.

Suitable for medium-sized establishments.

6. 2000L Microbrewery

Ideal for expanding microbreweries or brewpubs.

Allows for substantial production while preserving artisanal craftsmanship.

Great for meeting growing market demands.

Brewhouse System

A typical four-vessel brewhouse will include a Mash tun, Lauter Tun, Kettle and Whirlpool. Each of these tanks is dedicated to performing a single process, and is designed differently than similar vessel used for performing multiple processes.

Four-vessel systems offer the highest throughput and the most versatility. With proper vessel sizing, well laid out hard piping, and well-designed controls these brewhouses can be extremely large and only require one person to operate it. The ability to make more beer with less labor input, paired with gains in efficiency and quality control make the four-vessel brewhouse a worth while investment for breweries that intend to produce a lot of beer.

The alternative to a four-vessel production based brewhouse with dedicated process tanks, is two and three vessel systems with tanks that preform multiple processes. These combination tanks can be a more affordable way to start a brewery, they take up less floor space, and depending on your production goals, they might be able to last your business a very long time.

A typical two-vessel

Combination Mash Lauter Tuns are the first combination vessel in these smaller brewhouses line ups. This vessel should be sized to favor the Lauter operation, and have the mechanics for mixing mash and graining out.

Next inline is the combination of the Kettle and Whirlpool tanks. This combination vessel is designed and sized for being primarily a kettle, but is equipped with a tangential fitting for whirlpooling.

A three-vessel brewhouse is hybrid system that incorporates at least one combination vessel and two dedicated process vessels. For example, a medium sized brewery with a focus on heavily hopped beers might choose to go with a combination Mash Lauter Tun, a dedicated Kettle, and a dedicated Whirlpool. Whereas, someone focusing on lagers or feeding a distilling operation might go with a dedicated Mash Tun, dedicated Lauter Tun, and a combination Kettle/Whirlpool. Three-vessel systems don’t have the same output and versatility as four-vessel systems, but they will still out perform a two-vessel system and provide increased efficiency.

1000L Brewhouse for Reference

Brewhouse is consisted of mash tun, lauter tun, kettle tun, and whirlpool tun.

Two Vessels: (Mash lauter tun & Kettle whirlpool tun).

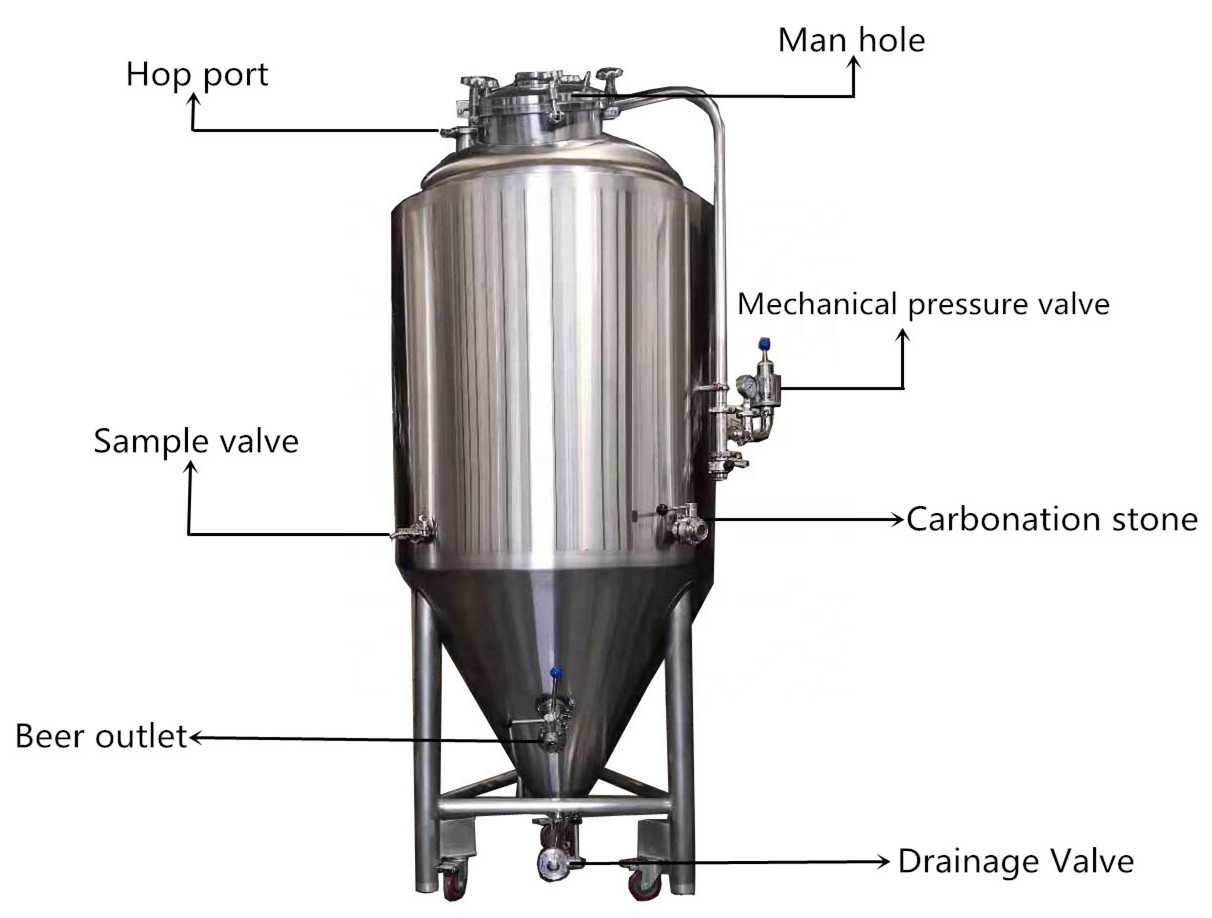

Fermentation tanks are where the magic happens. It’s important to have a precisely built vessel to condition your beer as it ferments. WEMAC offers fermentation tanks with ultra-precise welding and polishing, complete traceability, and material exactness to meet all international safety standards. From small, pub-size fermenters to towering outdoor tanks, we have the manufacturing capability and expertise to custom-build fermentation tanks of all sizes.

1.) Function: Use for keep wort fermentation or maturation.

2.) Component: It is consisted of Shadowless manhole, Mechnical relief valve, Aseptic valve, Pressure gage, Rotate racking arm, Butterfly valve, Solenoid valve and etc.

3.) Glycol jacket: Dimpled plate on cone side, cooling media: glycol water or alcohol water.

4.) Cooling method: dimple plate or glycol cooling jacket around tank.

5.) Cooling media: glycol water or alcohol water.

Configuration of beer brewing equipment

Cooling way | Ice water belt cooling |

Heat exchange area | 3.6m2 |

Material | SUS304 |

Inner thickness | 3.0mm |

External-Jacket(SUS304) thickness | 1.5mm |

inner surface polished accurancy | Ra0.4um |

Fermentation tank pressure | Design pressure 0.3MPa; Working pressure 0.15Mpa |

Cleaning System | CIP washing unit: Comprehensive cleaning |

Insulation | Polyurethane-thickness: 80mm |

Oval head cone bottom | thickness: 3.0mm |

Key Features of WEMAC Brewing Equipment

Quality Materials: WEMAC uses high-quality stainless steel for its brewing equipment, ensuring longevity and resistance to corrosion.

Advanced Technology: Our systems are designed with modern brewing technology to provide precise control over the brewing process.

Customization: WEMAC offers customization options, allowing you to tailor your brewing equipment to meet your specific needs.

Support and Training: We provide comprehensive training and support to help you get the most out of your brewing equipment.

Efficiency: WEMAC systems are designed for efficient brewing, helping you save time and resources.

Reliability: With a reputation for reliability, WEMAC brewing equipment is trusted by brewers worldwide.

Starting or expanding a microbrewery is an exciting endeavor, and WEMAC's range of brewing equipment in various batch sizes ensures you can find the perfect solution for your needs. Whether you're brewing for personal enjoyment or commercial success, WEMAC has the tools to help you craft exceptional beer.

FAQ

1. What is WEMAC's range of batch sizes for microbrewery equipment?

WEMAC offers microbrewery equipment in batch sizes of 100L, 200L, 300L, 500L, 1000L, and 2000L.

2. Is WEMAC brewing equipment suitable for both homebrewers and commercial breweries?

Yes, WEMAC's equipment caters to a wide range of customers, from homebrewers and small-scale breweries to larger commercial operations.

3. What material is used to make WEMAC brewing equipment?

WEMAC uses high-quality stainless steel, known for its durability and resistance to corrosion, in the construction of their brewing equipment.

4. Can I customize my brewing equipment from WEMAC to meet specific requirements?

Yes, WEMAC offers customization options to tailor your brewing equipment to your unique needs, ensuring it fits your brewing style and space.

5. Do they provide training and support for using their brewing equipment?

Yes, WEMAC offers comprehensive training and support to help you operate and maintain their brewing equipment effectively.

6. Is the brewing equipment designed with advanced technology for precise control over the brewing process?

Yes, WEMAC's systems are equipped with modern brewing technology to provide precise temperature and process control, ensuring consistent beer quality.

7. Can I expand my brewing capacity with WEMAC equipment as my business grows?

Yes, WEMAC offers larger batch sizes (up to 2000L) to accommodate the growth of your microbrewery.

8. Is WEMAC brewing equipment known for its reliability and performance?

Yes, WEMAC has a reputation for producing reliable and high-performance brewing equipment, trusted by brewers worldwide.

9. What are the space requirements for WEMAC microbrewery equipment?

The space required depends on the specific batch size and configuration of the equipment. WEMAC can provide guidance on space requirements for each system.

10. Can I use WEMAC brewing equipment for experimental or specialty brews?

Yes, the smaller batch sizes (100L, 200L) are ideal for experimenting with new recipes and brewing specialty beers.

11. WEMAC designs their systems with efficiency in mind to help brewers save on energy costs while maintaining brewing quality.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- 15 gallon jacketed fermenter

- home brewing distillation equipment

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- automatically brew equipment,50L Brewing equipment

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- dry hops addition

- hop additive gun

- hops addition gun

- pilot brewing system

- Microbrewery machine

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

Best 500L beer brewing equipment suppliers near me

The nearest brewery system suppliers-WEMAC,we supply beer brewing system with turn-key project.

provide beer equipment ...

Beer brewing equipment for bar

The beer brewing equipment for bar can be customized to produce.Beer brewing equipment for bar can be customized design,...

More >>856.png)

Beer brewing equipment supplier a whole of brewery system US

Professional manufacturer of beer brewery equipment,more than 60 years brewery production experience.Beer equipment incl...

More >>

WEMAC Beer brewing equipment micro brewery 100L 200L 300L 500L 1000L 2000L per batch ZXF

A typical two-vessel

Combination Mash Lauter Tuns are the first combination vessel in these smaller brewhouses line ups...

WEMAC 500L two vessel three bodies mash tank of beer brewery equipment ZXY

WEMAC 500L two vessel three bodies mash tank of beer brewery equipment can mash up to 500L at a time. If it is equipped ...

More >>

WEMAC 1000L 2 vessels beer brewing system brewery equipment made of stainless steel ZXY

WEMAC 2 container beer brewing system is made of high-quality stainless steel, 316L or copper outsourcing material, whic...

More >>

100L Stainless steel mash tank of making beer machine in Australia ZXY

The 100L Stainless steel mash tank of making beer machine is used in the mash process of brewing beer. It can mash up to...

More >>

SUS304 Beer brewing machine brewery equipment widely used in mini bar ZZ

we are the professional beer brewing equipment manufacturer and supplier,we are also the pharmaceutical equipment manufa...

More >>