WEMAC 500L two vessel three bodies mash tank of beer brewery equipment ZXY

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

WEMAC 500L two vessel three bodies mash tank of beer brewery equipment

In the world of craft beer brewing, precision and consistency are key to producing exceptional brews. The WEMAC 500L Two-Vessel Three-Bodies Mash Tank plays a pivotal role in this process. Let's dive into what this equipment is, how it functions, and why it's an essential component for brewers.

What is the Two-Vessel Three-Bodies Mash Tank?

The Two-Vessel Three-Bodies Mash Tank is a critical component of beer brewing equipment used in the mashing and lautering processes. It consists of three interconnected vessels:

Mash Tun: This is where the brewing process begins. Crushed grains are mixed with hot water in the mash tun. During this stage, enzymes present in the grains convert starches into fermentable sugars, creating a sugary liquid known as wort.

Lauter Tun: After mashing, the liquid wort is separated from the solid grain material in the lauter tun. This process, called lautering, is essential for extracting sugars and other soluble compounds from the grain.

Combined Kettle/Whirlpool: The liquid wort collected from the lauter tun is transferred to the combined kettle/whirlpool vessel. Here, the wort is boiled, and hops are added to impart flavor and bitterness. Additionally, the whirlpool function helps separate solid particles from the wort.

Advantages of two vessel three bodies mash tank

①Compared with the three-body three-device saccharification system, the overall area is more compact and small.

②The heating area of the steam jacket of the boiling pot is generally large and the heating speed is fast.

③The filter tank is above the rotary sink, which can achieve natural filtration (wort is filtered by gravity), the filtration speed is fast, the wort is clear and bright, even if the operation is wrong, there will be no phenomenon of deformation of the sieve plate caused by the compaction of the grain layer .

④The sinker is a vertical cylindrical slot design. Because it is a special sinker, the sinker is designed as a tangential sinker, so the separation effect of hop lees and thermal coagulum is better.

⑤When the wort is filtered, the boiling pot can prepare the spent grains water, and the spent grains can be washed while filtering, which can shorten the saccharification time by 30-50 minutes, and the utilization rate is higher than that of the two-unit saccharification system.

⑥ Generally, two batches can be brewed in one day. If you consider staying up late and working overtime, you can brew 3-4 batches a day. During the peak beer sales period, you can brew more wine in the shortest time.

Why is the WEMAC 500L Mash Tank Essential for Brewers?

Consistency: The precise control over the mashing process ensures consistency in every batch of beer. Brewers can adjust parameters like temperature and time to achieve specific flavor profiles.

Efficiency: This equipment streamlines the brewing process, saving time and energy. The lauter tun efficiently separates wort from spent grain husks, maximizing wort yield.

Versatility: The mash tank is adaptable and can be used to brew a wide variety of beer styles. Brewers can experiment with different grain bills, hop additions, and yeast strains to create unique brews.

Integration: The WEMAC 500L Mash Tank can seamlessly integrate into larger brewery setups, allowing for scalability as the brewery grows.

Quality Control: Precise temperature control and consistent wort production contribute to high-quality beer. Brewers can maintain the desired mash temperature throughout the process.

Cleaning and Maintenance: Routine cleaning and maintenance, including Clean-In-Place (CIP) procedures, ensure the equipment's longevity and prevent contamination.

The WEMAC 500L Two-Vessel Three-Bodies Mash Tank is a versatile and indispensable tool for craft brewers, enabling them to produce top-quality beer with efficiency and precision. Its role in mashing, lautering, and wort boiling contributes to the art and science of brewing, allowing brewers to explore their creativity while maintaining the highest standards of quality.

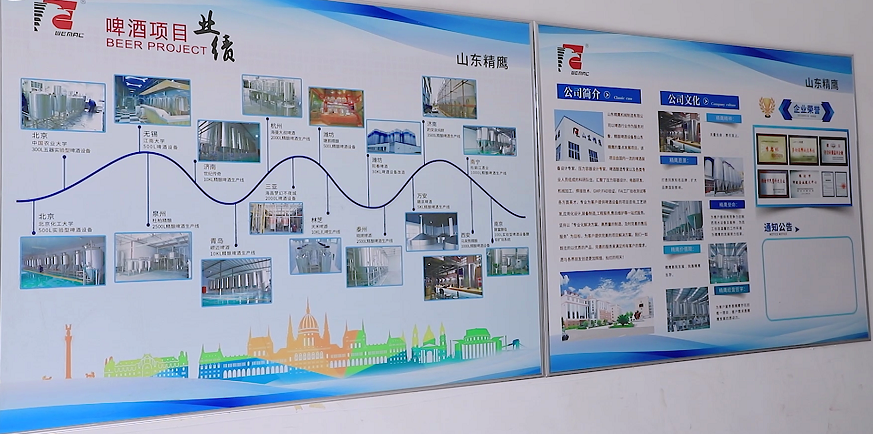

Advantages of WEMAC

WEMAC was established in 1958. It has been in the industry for many years and has always been among the top three in beer brewing system manufacturing. If you are willing to build a new brewery and establish a process, we are looking for partners and agents worldwide. For bars, we can provide you with services and design a complete system. We provide design, consulting, manufacturing and transportation services, as well as installation and training. If you have experience as a distributor, we can help you reach the local beer manufacturing market, and sincerely hope to hear from you.

FAQ

Q1: What is the 500L two-vessel three-bodies mash tank, and what is its role in a brewery?

A1: The 500L two-vessel three-bodies mash tank is a component of beer brewing equipment used in the mashing and lautering processes. Its primary role is to mix crushed grains with hot water, allowing enzymes to convert starches into fermentable sugars, ultimately producing wort for fermentation.

Q2: What are the three bodies in the mash tank, and how do they function?

A2: The three bodies in the mash tank typically refer to the mash tun, lauter tun, and combined kettle/whirlpool. The mash tun is where the grain and water are initially mixed. The lauter tun is used to separate the liquid wort from the solid grain material. The combined kettle/whirlpool is where the wort is boiled and hops are added.

Q3: What is the capacity of the WEMAC 500L mash tank, and is it suitable for small breweries?

A3: The WEMAC 500L mash tank has a capacity of 500 liters (approximately 132 gallons) and is well-suited for small to medium-sized breweries. It allows for the production of a significant volume of wort for fermentation.

Q4: How is temperature control achieved in the mash tank during the mashing process?

A4: Temperature control in the mash tank is typically achieved through a combination of heating elements and temperature sensors. Breweries can adjust the temperature as needed to create optimal conditions for enzymatic activity during mashing.

Q5: What is the lautering process, and why is it important in brewing?

A5: Lautering is the process of separating the liquid wort from the solid grain material after mashing. It is crucial because it extracts sugars and other soluble compounds from the grain, leaving behind the spent grain husks. The wort collected in the lauter tun is then boiled and fermented to make beer.

Q6: Can the WEMAC 500L mash tank be used for different beer styles and recipes?

A6: Yes, the mash tank can be used to brew a wide variety of beer styles and recipes. Brewers can adjust the mash temperature, grain bill, and hop additions to achieve different flavor profiles and characteristics.

Q7: What cleaning and maintenance procedures are necessary for the mash tank?

A7: Regular cleaning and sanitation are essential to prevent contamination. Breweries typically follow strict cleaning protocols, including Clean-In-Place (CIP) procedures. Routine maintenance, such as inspecting seals and valves, ensures the tank's proper operation and longevity.

Q8: Can the WEMAC 500L mash tank be integrated into a larger brewery setup?

A8: Yes, the mash tank can be integrated into a larger brewery setup, including additional vessels for fermentation, conditioning, and packaging. It is a versatile component that can adapt to different production scales.

Q9: Is the WEMAC 500L mash tank customizable to specific brewery requirements?

A9: Yes, WEMAC offers customization options to meet specific brewery requirements, such as control systems, additional features, or accessories tailored to the brewer's needs.

Q10: How is the wort transferred from the mash tank to the fermentation vessel?

A10: Wort transfer is typically accomplished using pumps, hoses, and pipelines to move the liquid from the mash tank to fermentation vessels where yeast is added for fermentation.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- home brewing distillation equipment

- craft brewery equipment for sale, craft beer equip

- beer brewing equipment

- complete brewery for sale

- Nano brewery equipment, brewing systems manufactur

- 15 gallon jacketed fermenter

- automatically brew equipment,50L Brewing equipment

- dry hops addition

- hops addition gun

- mixing tank manufacturers

- hop additive gun

- pilot brewing system

- Craft beer making equipment for Malaysia

- CIP system

- Microbrewery machine

- professional Cleaning in place equipment

FEATURED PRODUCTS

Best 500L beer brewing equipment suppliers near me

The nearest brewery system suppliers-WEMAC,we supply beer brewing system with turn-key project.

provide beer equipment ...

Beer brewing equipment for bar

The beer brewing equipment for bar can be customized to produce.Beer brewing equipment for bar can be customized design,...

More >>856.png)

Beer brewing equipment supplier a whole of brewery system US

Professional manufacturer of beer brewery equipment,more than 60 years brewery production experience.Beer equipment incl...

More >>

WEMAC Beer brewing equipment micro brewery 100L 200L 300L 500L 1000L 2000L per batch ZXF

A typical two-vessel

Combination Mash Lauter Tuns are the first combination vessel in these smaller brewhouses line ups...

WEMAC 500L two vessel three bodies mash tank of beer brewery equipment ZXY

WEMAC 500L two vessel three bodies mash tank of beer brewery equipment can mash up to 500L at a time. If it is equipped ...

More >>

WEMAC 1000L 2 vessels beer brewing system brewery equipment made of stainless steel ZXY

WEMAC 2 container beer brewing system is made of high-quality stainless steel, 316L or copper outsourcing material, whic...

More >>

100L Stainless steel mash tank of making beer machine in Australia ZXY

The 100L Stainless steel mash tank of making beer machine is used in the mash process of brewing beer. It can mash up to...

More >>

SUS304 Beer brewing machine brewery equipment widely used in mini bar ZZ

we are the professional beer brewing equipment manufacturer and supplier,we are also the pharmaceutical equipment manufa...

More >>