Best plate heat exchanger for beer brewery

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

Best plate heat exchanger for beer brewery

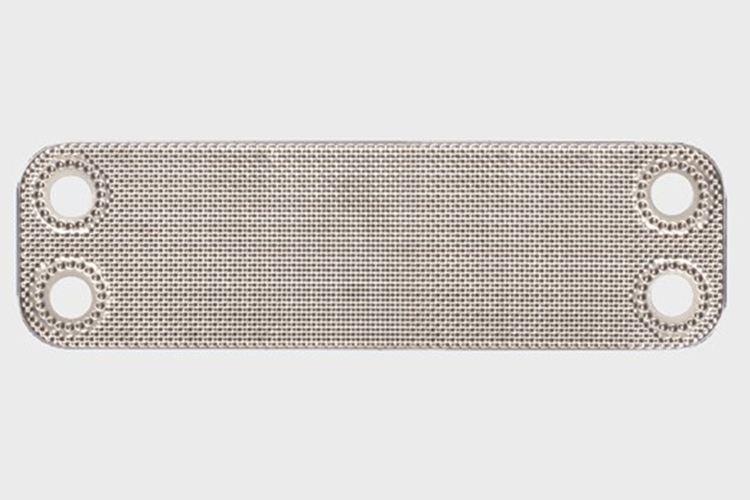

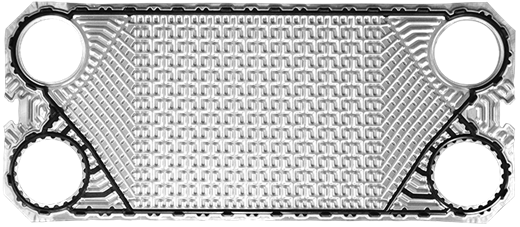

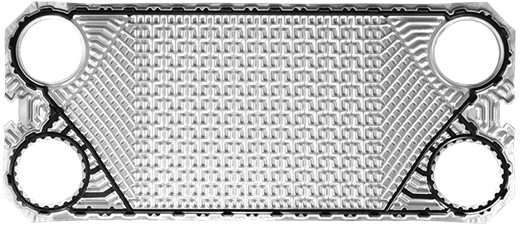

The WEMAC plate heat exchanger (PHE) series is extensive, including multiple types of heat exchangers, suitable for all types of industries, with multiple applications, including heating, cooling, condensation and evaporation. Our design factors give PHE the flexibility to ensure the best fit, can be expanded to meet future needs, and can be easily adjusted to accommodate changes in capacity.

Our traditional plate heat exchanger is the first choice for standard tasks. Multifunctional design and high thermal efficiency make them a perfect solution for a wide range of applications.

What does this mean to you-Best plate heat exchanger for beer brewery

We focus on developing plate heat exchangers in close cooperation with our customers. Because we understand the process behind your application, each solution is customized and configured to suit you and your business.

Our extensive printing plate product portfolio and pattern options ensure that we always have a solution that is perfectly suitable for you. Our model creates ideal turbulence and makes full use of the available pressure drop in any task.

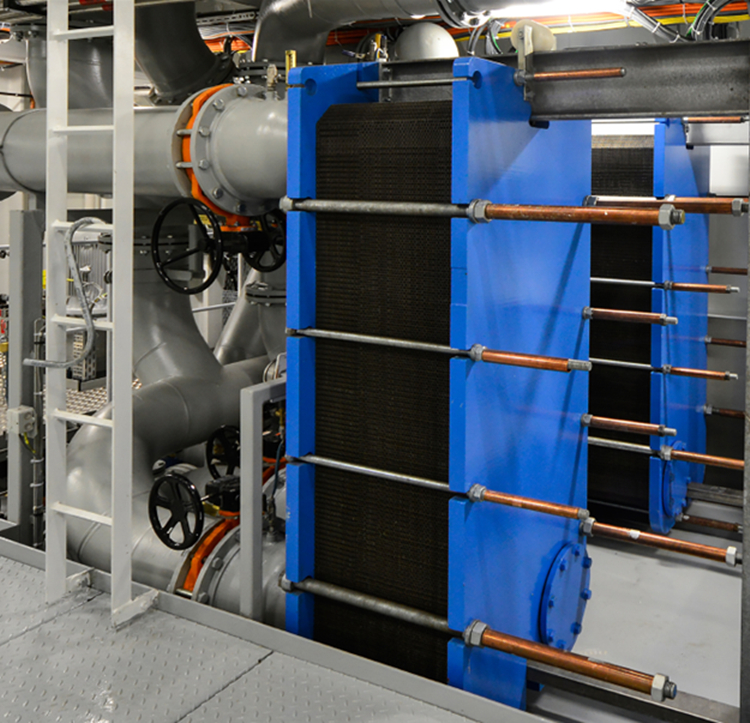

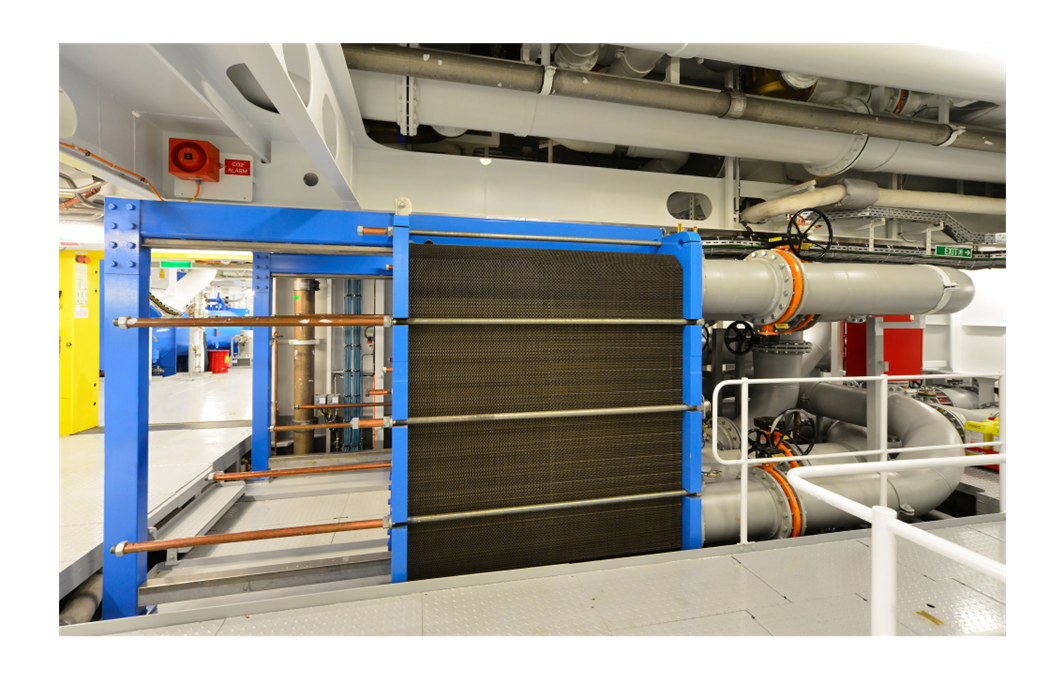

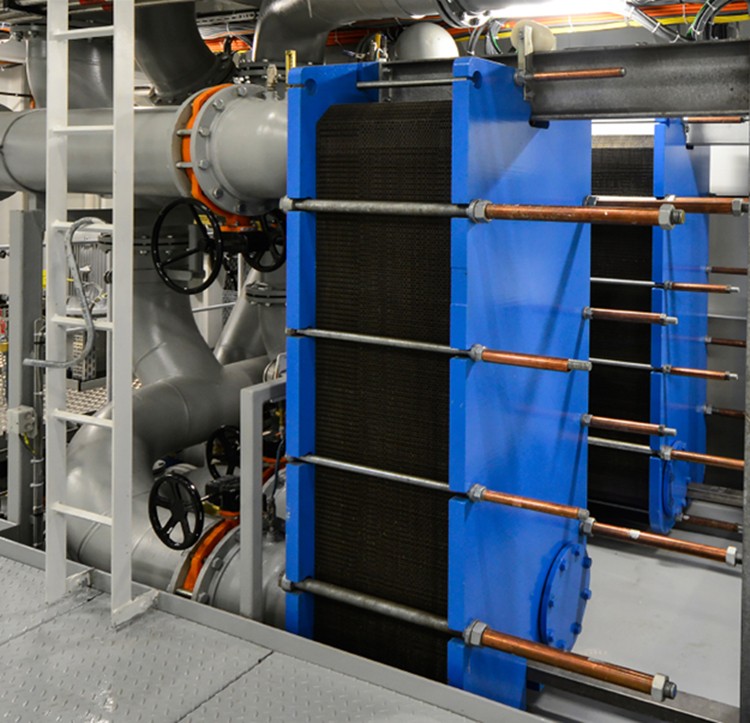

Always an efficient choice

We design one-way solutions as much as possible because they are the first choice for almost all tasks. Since all connections are at the head, you can inspect, clean or repair without disconnecting the heat exchanger from the pipe. With WEMAC heat exchanger, installation and maintenance are simple, fast and convenient.

The design space requirement of WEMAC heat exchanger is extremely small, energy consumption is significantly reduced, and the number of plates required to achieve the best performance is reduced, so the future is considered in the design.

Advantage-Best plate heat exchanger for beer brewery

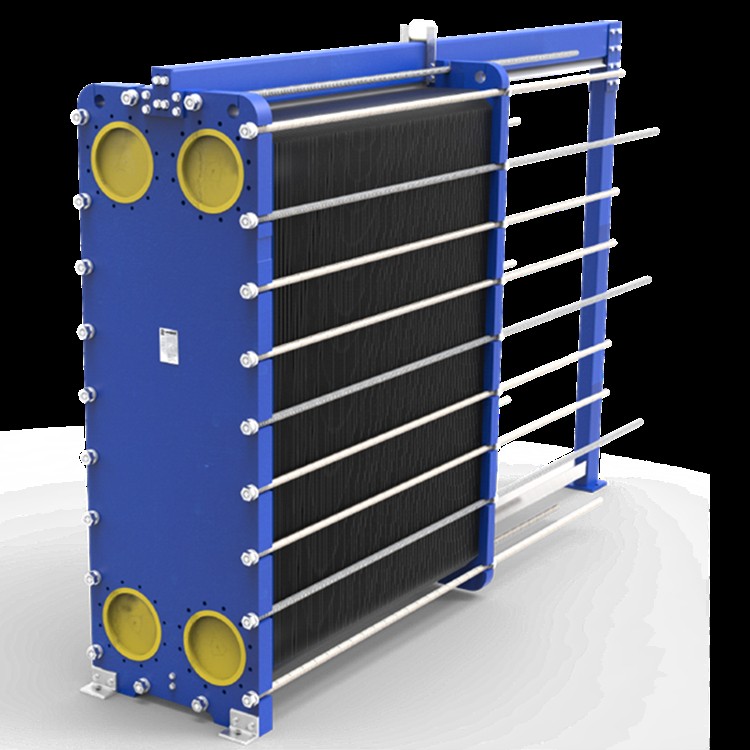

Compact design requires less space than shell and tube

Large heat exchange area

Scalable solutions because they can increase heat transfer by adding more plates

The temperature can be controlled even in small differences

Avoid cross-contamination by ensuring the special function of preventing the mixing of two process fluids

PHE requires less volumetric flow, which means lower costs in terms of space, pipes and pumps

Due to higher turbulence, less fouling

Easy to maintain, no extra space for disassembly

Specially designed high-efficiency fluid distribution with corrugated pattern to ensure the highest overall heat transfer rate

Durable gasket, ergonomic design, easy to maintain.

Application-Best plate heat exchanger for beer brewery

Our Farad line of PHE heat exchangers covers most applications with a wide range of capacities. They are suitable for cooling and heating in a range of industries such as marine, industrial, chemical processing, petrochemical, HVAC, power, pharmaceutical or food industry applications.

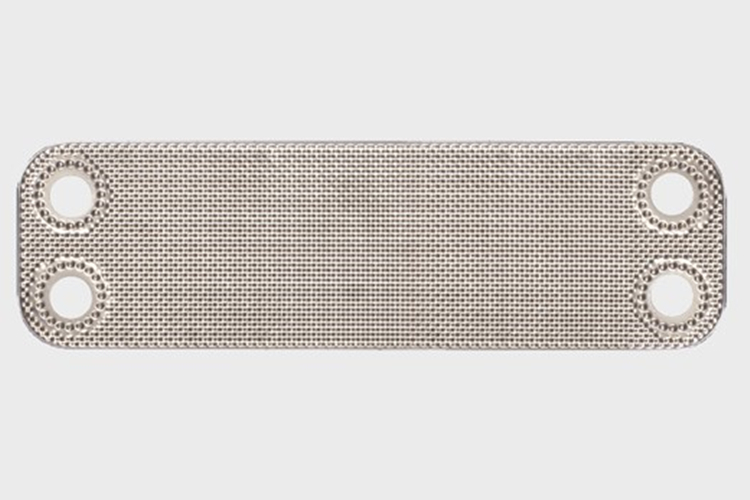

Material-Best plate heat exchanger for beer brewery

The materials of all PHE components have been carefully selected to meet the requirements for optimized performance and extended service life. Stainless steel is used for standard operations, and when sea water is involved, titanium is chosen to improve corrosion resistance.

quality

Our heat exchanger products meet the requirements of industry regulations and are guaranteed by a quality system recognized by a third party.

Selection Guide-Best plate heat exchanger for beer brewery

industry

Power plant central or auxiliary cooling

Chemistry

Food and beverage preparation

Pharmaceutical industry

Heating

Cooling

Condensation

FAQ

Q1: What is a plate heat exchanger, and why is it important for a beer brewery?

A1: A plate heat exchanger is a device used to transfer heat from one fluid to another without direct contact between them. In a beer brewery, it plays a crucial role in the cooling and heating processes during wort production and fermentation. It helps maintain precise temperature control, which is essential for achieving consistent and high-quality beer.

Q2: What makes a plate heat exchanger the best choice for a beer brewery?

A2: The best plate heat exchanger for a beer brewery should have several key features. It should be made from high-quality stainless steel, ensuring sanitary conditions and resistance to corrosion. Additionally, it should have a compact design, high heat transfer efficiency, and easy maintenance to optimize the brewing process and reduce energy consumption.

Q3: How does a plate heat exchanger benefit beer production?

A3: A plate heat exchanger enhances beer production in several ways. It enables rapid cooling of hot wort after boiling, preventing undesirable off-flavors and promoting the formation of a clean beer profile. During fermentation, it allows precise temperature control, which is crucial for yeast activity and flavor development. Overall, it improves the efficiency and consistency of the brewing process.

Q4: Can a plate heat exchanger handle different volumes of beer production?

A4: Yes, plate heat exchangers come in various sizes and configurations to accommodate different volumes of beer production. Whether you are a small craft brewery or a large-scale operation, there are plate heat exchangers available that can meet your specific production requirements.

Q5: Is it easy to clean and maintain a plate heat exchanger for beer brewing?

A5: Yes, plate heat exchangers are designed for easy cleaning and maintenance. The compact design and removable plates allow for efficient cleaning and sanitation, which is vital for maintaining the quality and hygiene of the beer production process.

Q6: Are plate heat exchangers energy-efficient for beer brewing?

A6: Yes, plate heat exchangers are known for their energy efficiency. Their compact design and large heat transfer surface area facilitate efficient heat exchange, reducing energy consumption during the cooling and heating processes in the brewery.

Q7: Can I integrate a plate heat exchanger into my existing beer brewing setup?

A7: Absolutely! Plate heat exchangers are versatile and can be easily integrated into existing beer brewing setups. They can be customized to fit specific space and flow requirements, making them a practical choice for upgrading or expanding your brewery operations.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- 15 gallon jacketed fermenter

- home brewing distillation equipment

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- automatically brew equipment,50L Brewing equipment

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- dry hops addition

- hop additive gun

- hops addition gun

- pilot brewing system

- Microbrewery machine

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

Best plate heat exchanger for beer brewery

The WEMAC plate heat exchanger (PHE) series is extensive, including multiple types of heat exchangers, suitable for all ...

More >>

500L Top quality craft beer brewery equipment

Double vessels craft beer brewing brewhouse for sale,mash/kettle tun + lauter/whirlpool tun are all made of high quality...

More >>

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Build me a 1500L beer brewery

mini beer brewery machine from 50L,which is suitable to use in home and family brewing,and micro beer brewery machine fr...

More >>

Best 500L beer brewing equipment suppliers near me

The nearest brewery system suppliers-WEMAC,we supply beer brewing system with turn-key project.

provide beer equipment ...

Best 500L beer brewhouse brewpub equipment

10hL steam heating Brewkit,most popular for the home brewing and small scale commercial brewery / brewpub.

Firstly,it c...

500L Steam heating beer brewery system Chinese suppliers ZXF

500L steam jacketed heating brewhouse,mash/kettle tun and lauter/whirlpool tun combination,PLC automaticlly control,suit...

More >>

beer brewing equipment manufacturers

Which is the best beer equipment manufacturer? How much investment does beer equipment need? What is included in the bee...

More >>