Best Automatically PLC Control In Microbrewery

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

Best Automatically PLC Control In Microbrewery

In the dynamic world of microbreweries, where precision meets innovation, the integration of advanced control systems is paramount. Programmable Logic Controllers (PLCs) serve as the brain of automated microbreweries, ensuring seamless operation, precise control, and the ability to craft a diverse array of high-quality beers. today we recommend the best PLC control systems for microbreweries, unlocking a new level of efficiency and creativity in the brewing process.

Automatically PLC Control panel In Microbrewery

The PLC control part just like the head of body,when thinking of the control unit here. I have some experience using and programming PLCs, but I don't have a good handle on what's available out there, especially when analog control is involved.

131447.jpg)

The brewery I'm designing in my head would probably have 15-20 temperature/pressure sensors, which would control about as many valves, pumps, motors, etc.Data logging is also a plus for a beer brewery.

A question is how cheap and how much software one has to write to make it function. The hardware is fairly common with careful research and incremental purchase you could add points as you go. Belimo proportional control ball valves are another item that shows up regularly on ebay these days. For flow meters the Malema line are also found on ebay for a reasonable price in the 1 gpm flow range.

PLC controlled system based on the 22 G1 series hardware and monitor temperatures, flows, pressures, to control liquid levels, liquid flows, gas flows to burners, pumps, conveyors, malt mill, exhaust system. With the current configuration there are about 30 analog points and 32 digital points in use.The software is an ongoing effort with learning how to incorporate SQL database functions beyond point configuration tables to develop and implement recipe formulation like other recipe formulation programs. The current goal is to be able to formulate recipe, pour ingredients into hopper, attach fermenter to CFC connection, press auto run button on touch screen and walk away to do other brewing activities while system takes care of brewing process.

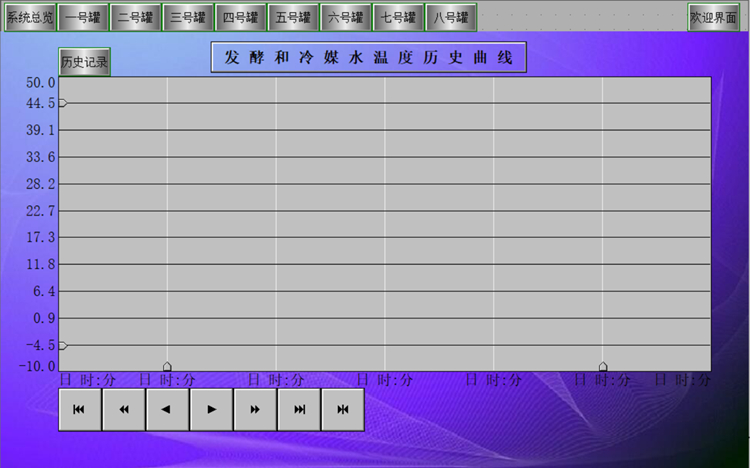

PLC Brewery Control screen in craft beer brewery:

The PLC control can help to realize a smart brewing process in breweries.

In a craft beer brewery plant, the control system is basic and primary on monitoring and operation functions.

It mainly maintain the setting temperature in the brewhouse or unique fermenter via correctly commanding the heating or cooling machine (they are normally steam boiler, burner, electric heating elements, glycol cooling system etc.), then we can also start or close pumps, motors on a panel. According to the automation level, here are PID control panel and PLC control panel.

Welcome pages and flow chart of whole brewing process in the PLC panel:

The welcome pages shows the flow chart of beer brewing,from milling malt to mashing/boiling/lautering/whirlpooling/fermentation/cooling/filtering/bottle-beer.

At the same time, it can be connected with pneumatic valves to realize automatic equipment control,instead of manuel valves operation in micro beer brewery.

In the miniature craft beer equipment system, the PLC panel can display the wort temperature status of multiple fermentation tanks, and monitor the temperature in the tank through the temperature signal output by the temperature sensor. The temperature signal is transmitted as an electrical signal. The fermentation temperature curve can be traced back to the historical record.

Features of PLC control touch screen and panel in microbrewery:

1. It is more suitable for brewhouse rather than fermentation process.

2.It can achieve setting several resting temperatures according to various recipes in a direct heated step-mashing process.

3.It shows the brewing flow chart and the brewing process duing beer making and on the touch screen to bring a visual brewing process.

4.It shows all pneumatic valves on touch screen to bring a easier and smarter control experience.

5. It is able to realize a remote control via adding internet model,even by your phone and your paid in a far distence.

6. Which is intelligent level is greatly effected by the hardware used on the brewery.

The best PLC control systems for microbreweries represent a convergence of precision, innovation, and efficiency. By embracing these advanced control solutions, microbreweries can elevate their automation capabilities, unlock new levels of creativity, and consistently produce high-quality beers that captivate the palates of enthusiasts around the world.

FAQ

Q1: What is a PLC, and why is it essential in microbrewery automation?

A1: A Programmable Logic Controller (PLC) is a digital computing device used to control various electromechanical processes. In microbrewery automation, PLCs serve as the central control system, managing and optimizing brewing processes for efficiency, precision, and consistency.

Q2: Can these PLC control systems be adapted to both small and large-scale microbrewery operations?

A2: Yes, the recommended PLC control systems are designed to be scalable, accommodating both small and large-scale microbrewery operations. This scalability allows breweries to grow and adapt their automation capabilities as needed.

Q3: How do PLC control systems contribute to the consistency and quality of craft beers in microbreweries?

A3: PLC control systems ensure precise control over brewing parameters, contributing to the consistency and quality of craft beers. They enable brewers to monitor and adjust variables, resulting in reliable and repeatable brewing processes.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- 15 gallon jacketed fermenter

- home brewing distillation equipment

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- automatically brew equipment,50L Brewing equipment

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- dry hops addition

- hop additive gun

- hops addition gun

- pilot brewing system

- Microbrewery machine

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

Beer brewhouse and fermentation tanks microbrewery

WEMAC-Main product categories:

Craft Beer equipment,Cider making machine,Beer brewing machine,beer plant,stainless stee...

Pro two vessels 5BBL craft brewery in Michigan

Professional beer brewhouse sale well in Michigan state,turnkey brewery services suppliers,Combined of malt milling syst...

More >>

Turnkey beer brewing system uk

The turnkey beer system program includes site planning, layout, equipment design, technical communication, installation ...

More >>

2500L Turnkey beer microbrewery brewhouse

2500L commercial beer brewery system turnkey project suppliers,the four vessels combination can brewing beer at least 4 ...

More >>

Best Automatically PLC Control In Microbrewery

PLC Brewery Control screen in beer brewery

The PLC control can help to realize a smart brewing process in breweries.

I...

1HL 1BBL home beer brewing brewhouse manufacturer near Los Angeles ZXF

Two vessels craft beer brewing system manufacturer in Los Angeles,provides system from factory to home,electric heating ...

More >>

high quality brewery micro equipment 500l

High quality brewery micro equipment 500l includes two vessels brewhouse,three vessels brewhouse,Four vessels brewhouse,...

More >>

2 Vesssels Brewhouse equipment for beer brewing ZXF

Micro beer brewery system for people those new to beer brewing,one stop service from brewery design/manufacturing/traini...

More >>