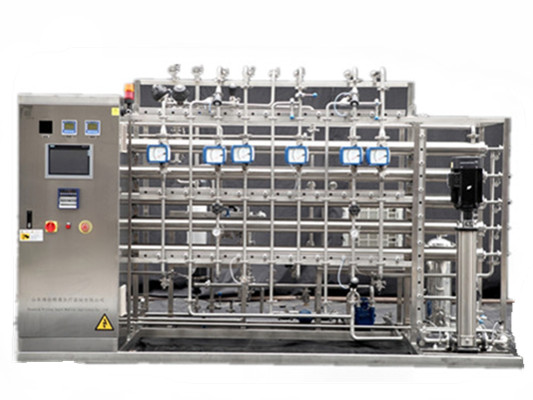

Ultrafiltration water purification equipment for sell from Chinese factory ZZ

- * Processing : Water purification, pure water treatment

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

- * Processing : Water purification, pure water treatment

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

ultrafiltration water purification equipmentwater purification systemultrafiltration water purification system for sellwater purification equipment from Chinese factory

The special ultrafiltration equipment for pollution engineering removes impurity particles of a certain size in the water by means of physical retention. Driven by pressure, water, organic low molecules, inorganic ions and other small-sized substances in the solution can reach the other side of the membrane through the micropores on the fiber wall, and large-sized bacteria, colloids, particles, and organic macromolecules in the solution The substance cannot penetrate the fiber wall and is retained, so as to achieve the purpose of sieving different components in the solution.

The combination of ultrafiltration membrane filaments into a component that can be connected to an ultrafiltration system is called an ultrafiltration membrane module. Ultrafiltration membrane modules are divided into three types: internal pressure type, external pressure type and submerged type. The driving force of submerged ultrafiltration membrane filtration is the pressure difference between the vacuum inside the membrane tube and the atmospheric pressure.

The filter is a device that uses ultrafiltration technology to purify water. The difference from other water purification equipment is the use of ultrafiltration membranes. Ultrafiltration membrane is a kind of microporous filtration membrane with consistent pore size specifications and rated pore size range of 0.01-0.001 microns. The membrane filtration method using ultrafiltration membrane with pressure difference as the driving force is ultrafiltration membrane filtration.

The membrane in the ultrafiltration equipment is a microporous filtration membrane with the same pore size and the rated pore size range of 0.001-0.02 microns. The membrane filtration method using ultrafiltration membrane with pressure difference as the driving force is ultrafiltration membrane filtration. Ultrafiltration membranes are mostly made of acetate fibers or polymer materials with similar properties. It is suitable for the separation and concentration of solutes in the processing solution, and is also often used for the separation of colloidal suspensions that are difficult to complete with other separation technologies. Its application fields are constantly expanding. Membrane filtration driven by pressure difference can be divided into three types: ultrafiltration membrane filtration, microporous membrane filtration and reverse osmosis membrane filtration. Their distinction is based on the size or molecular weight of small particles that the film can retain.

This set of full automatic multiple water softening equipment has the following characteristics:easy operation,professional knowledge is not required for users,full automatic control.just need to does salt regularly.continuous supplying water,double tanks system(one in production and one for preparation),produce water 24 hours.up-flow regeration:using softened water to wash and regenerate,gurantee low salt consumption and high water quality.simple maintenance,almost zero trouble.

This equipment mainly uses ion exchange method to soften water. The ion exchange method uses the cations in the cation exchanger (such as Na+, H+, NH4+) to exchange the hardening ions (Ca2+, Mg2+) in the water to obtain softening. .

The mechanism of action is: when the raw water containing hardness ions passes through the sodium resin in the exchange tank, the Ca2+ and Mg2+ in the water are exchanged and adsorbed by the Na+ in the resin, and the Ca2+ and Mg2+ are removed to remove the carbonate or non-carbonate hardness, which is softening. water. After the resin absorbs a certain amount of Ca2+ and Mg2+, it must be regenerated. Regeneration is to wash the resin layer with salt water in the salt tank. The Na+ in the brine replaces the hardness ions on the resin into the water, and is discharged out of the tank with the regenerated liquid to restore the resin exchange capacity and continue to soften the water.

Application areas of softened water equipment:

Industrial boilers, cooling circulating water, steelmaking, steel rolling, large transformers, civil hot water boilers,

Air conditioning and other occasions.

Water softening equipment capacity configuration: configure according to customer requirements.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- 15 gallon jacketed fermenter

- home brewing distillation equipment

- brewing equipment manufacturers uk,home brewing eq

- sovereign stainless steel fermenter

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- automatically brew equipment,50L Brewing equipment

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- dry hops addition

- hop additive gun

- hops addition gun

- pilot brewing system

- Microbrewery machine

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

Purified water generation and storage system supplier ZXF

Reverse osmosis technology is a well-developed desalination technology in the world, and it is also the most widely used...

More >>

Pharmaceutical use 500L/H purified water system with reverse osmosis unit

Pharmaceutical use 500L/H purified water system with reverse osmosis unit is made by professional manufacturer WEMAC(Sha...

More >>

WEMAC SUS304 Automatic Water treatment RO system and EDI treatment widely used in food beverage industry

The main part of the whole set of equipment is RO water treatment equipment and EDI module,According to the water qualit...

More >>

professional industrial and medical water purification system made in Chinese factory ZZ

Our water purification equipment is divided into the following categories:

1. Ultrafiltration equipment,•Ultrafiltratio...

Professional purified water system for sale Chinese supplier ZZ

product features:

(1) It has high mechanical strength and service life;

(2) It can function under lower operating pres...

professional industrial water purification system hot sell in Zambia from Chinese supplier ZZ

Our company is able to provide customers with corresponding water treatment equipment for the different water quality in...

More >>

Mobile container purified water system widely used in outdoor water treatment from Chinese factory ZZ

Mobile container-type water treatment equipment is a kind of integrated water purification unit that can move the water ...

More >>

Auto control industrial water purification system UF compound membrane from Chinese supplier ZZ

1. UF mineralization water filter use automatic control and semi-control.

2. UF mineralization water filter when no pow...