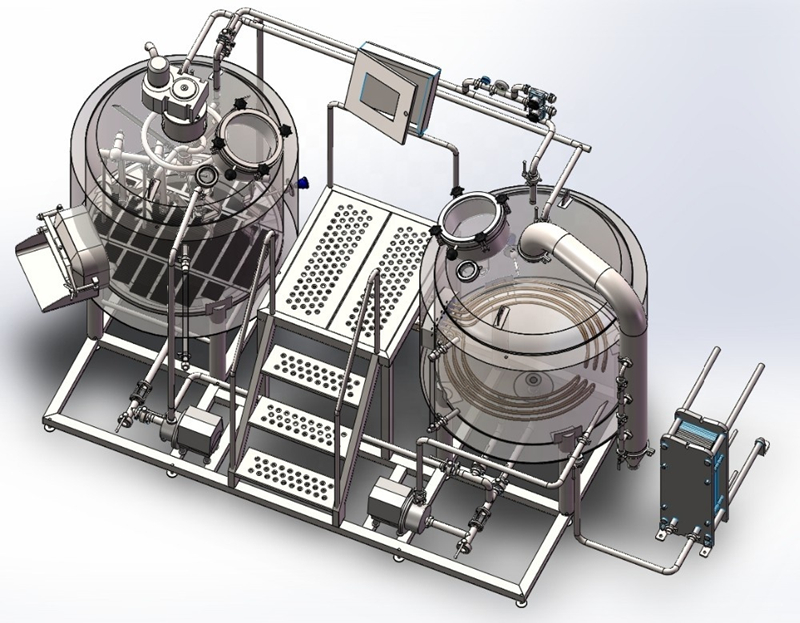

2500L turnkey beer brewing sysytem for sale factory WEMAC G048

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

complete brewing system for salebest brewing equipment brew systems for sale beer brewing plant for sale

The use of pressure fermentation can inhibit the proliferation of yeast, reduce the excessive metabolic byproducts caused by the temperature rise, prevent the production of excessive amounts of higher alcohols and esters, and at the same time facilitate the reduction of diacetyl and ensure the carbon dioxide in the wine. content. The relationship between CO2 content in beer and tank pressure and temperature is:

CO2(%, m/m)=0.298+0.04p-0.008t

Where p - tank pressure (pressure gauge reading) (MPa)

t -- beer product temperature (°C)

Fermentation anomaly:

Fermentation suspension

The fermentation of fermentation broth is called "no hypoglycemic".

The reasons for this phenomenon are: malt nutrition is not enough, oligosaccharide content is too high, α-amino nitrogen is insufficient, acidity is too high or too low; yeast cohesiveness is strong, causing early flocculation and sedimentation; yeast degeneration, mutation causes no Hypoglycemic; yeast spontaneous mutation, resulting in respiratory deficient yeast.

Solution: If it is strong by yeast, it will cause early flocculation and sedimentation. The fermentation temperature can be adjusted by increasing the amount of wort ventilation, and the temperature is lowered to near the final fermentation degree to prolong the high temperature period. However, it will improve the coagulation performance of the yeast, and it is best to solve this phenomenon by separating the coagulated yeast strain. If it is due to yeast degradation, mutations lead to no hypoglycemic. It can be solved by replacing the new yeast species. If it is caused by spontaneous mutation of yeast, it produces respiratory-deficient yeast. The strain can be re-expanded or replaced from the original strain.

In addition, in the preparation process of wort, it is necessary to strengthen the hydrolysis of protein, appropriately reduce the decomposition temperature of protein, and prolong the decomposition time of protein; in saccharification, the saccharification temperature should be properly adjusted, the hydrolysis in the low temperature section should be strengthened, and sufficient saccharification time should be ensured and adjusted. The pH of the sputum.

Send a Message

If you want to ask anything just fill in the form below and send us.

Name: Otto Hall time:2020-05-08 14:07:47

Energy-saving and safe, easy to operate. very good!

Name: Gwendolyn time:2019-11-20 13:50:08

The beer brewing sysytem is awesome! Will keep the cooperation.

Name: Elmer Cloma time:2019-11-15 10:26:51

Very good beer brewing sysytem. The materials is super. The design is rational.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- 15 gallon jacketed fermenter

- home brewing distillation equipment

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- automatically brew equipment,50L Brewing equipment

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- dry hops addition

- hop additive gun

- hops addition gun

- pilot brewing system

- Microbrewery machine

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Turnkey brewing equipment supply near me

Turnkey brewing equipment supply-WEMAC can supply turnkey brewing equipment system.We are one of the most excellent turn...

More >>294.jpg)

All in one brewing system Australia

WEMAC beer equipment manufacturer is a well-known all in one brewing system, with more than 60 years of experience in th...

More >>

10HL 1000L Romania turnkey beer brewery equipment ZXF

1000L electric steam heating beer brewing brewhouse,sell well in Romania.Personalized customization, a variety of heatin...

More >>

Stainless steel boiling tank beer brewing brewery turnkey system supplier ZXF

All size brewery for sale,WEMAC Provide turnkey service for beer brewing system,Professional brewers and technical engin...

More >>

WEMAC 3000L Turnkey beer brewing brewery foul vessels brewhouse manufacturer ZXF

WEMAC specializes in undertaking large, medium and small beer brewing turnkey projects, the quality of WEMAC meets the G...

More >>

Modern beer making brewery turnkey brewhouse system made of high quality stainless steel ZXF

WEMAC provides a turnkey system for a modern beer brewing factory. From the storage and crushing of raw materials and ma...

More >>

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

Grain Handling

Heating System - Electric, Steam, or Direct Fire

Brew House Tanks

Brew House Controls

Pumps

Glycol &...