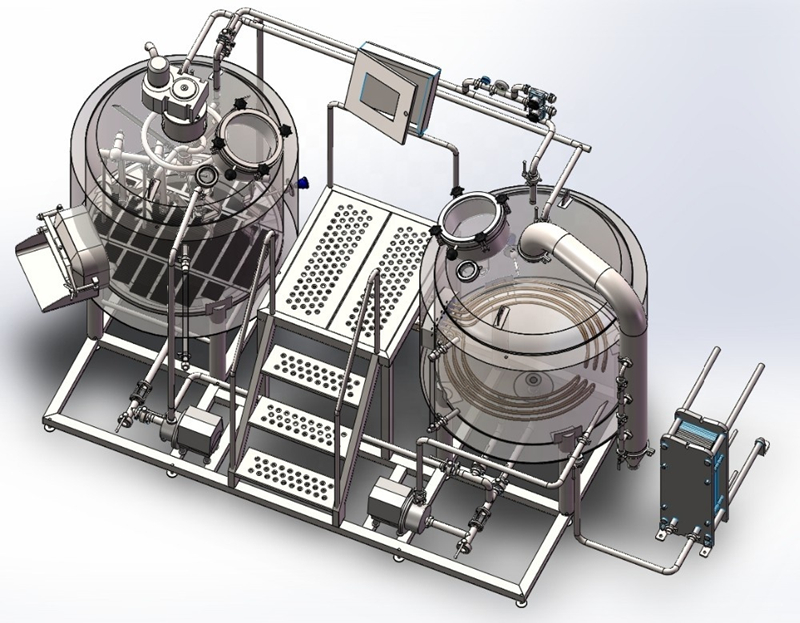

100HL turnkey brewery equipment for sale china factory WEMAC G055

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

- * Processing : Fermenting Equipment, Beer Brewing

- * Brand : WEMAC

- * Condition : New

- * Material : SUS 304 316

- * Size : To Be Determined

- * Place of Origin : Weifang, China (Mainland)

- * Control system : AUTO/MANUAL

- * Warranty : Within 24 months against the date of B/L

- * Voltage: : To Be Determined (220V/ 380V/ 415V)

large brewing equipment large scale brewing equipment large beer brewing equipment ale brewing equipment

While the feed hot water pump is closed, the lower feed valve is automatically opened. When a material is detected in front of the pump, the pump will automatically start and start to feed mash into the filter press from the bottom. When the filter press When a material is detected at the top, it means that the material in the filter press is full. At this time, the exhaust valve at the top of the filter press is automatically closed.

Backflow When the material in the filter press is full, the upper feeding valve opens automatically, and the material is fed from the top and bottom of the filter press at the same time to ensure that the material is evenly distributed in the filter press. At the same time, the return valve is opened to make filtering The turbid wort is passed through the balance tank and returned to the saccharification pot. When the filtered wort is clear, the return valve is automatically closed.

Filtration When the backflow is over and the backflow valve is closed, wort is started into the temporary storage tank or the boiling pot. When no material is detected in the saccharification pot, the pump will automatically stop.

Flushing When no material is detected in the saccharification pot, the hot water pump is automatically started. Hot water is flushed into the saccharification pot for flushing. When the flushing time is reached, the hot water pump is automatically turned off. At the same time, the decanter pump starts automatically, and the hot water in the saccharification pot is driven into the filter press. When no material is detected in the saccharification pot, the decanter pump automatically stops.

Prewashing When the pump is stopped, the hot water pump starts automatically (the flow of the hot water pump is set in advance), entering from the upper and lower parts of the "odd plate", and exiting from the upper and lower parts of the "even plate". (Or go in from the top and bottom of the "even board", and go out from the top and bottom of the "odd board", alternately). When the time is up, it will automatically enter the washing process.

Send a Message

If you want to ask anything just fill in the form below and send us.

Write a review

Products

- Beer brewery equipment

- Craft brewing equipment

- Home brewing equipment

- Microbrewery equipment

- Commercial brewing equipment

- Industrial brewery equipment

- Pilot brewing system

- Brewhouse & Mash system

- Fermentation tank

- Bright / Brite tank

- CIP system

- Beer filling machine

- Pasteurizer

- Hop gun

- Yeast propagation equipment

- Beer concentration equipment

- Carlsberg flask

- Reverse osmosis water filtration systems

- Mobile water treatment systems

- Water Purification Equipment

- WFI equipment

- Purified water tank

- CIP system

- Multi effect water distiller

- Pure steam generator

- WFI tank

- Solution preparation tank

- Tube heat exchanger

- Storage and distribution system

- Liquid preparation system

- Demineralized water system

- Vapour compressor

News & Exhibitions

- Why Beer Concentration Matters: Unpacking the Standard ABV Range

- Why Every Craft Brewer Needs a Pilot Beer Brewing System

- Top 5 Benefits of Using a Pilot Beer Brewing System for Small Breweries

- Setting Up a Microbrewery? Why Turnkey Equipment Might Be Right for You

- How Nano Brewery Equipment is Changing Experimental Brewing: A Deep Dive into Small-Scale Innovation

- Essential Craft Beer Equipment for Starting Your Brewery

- Integrating Smart Equipment into Your Microbrewery

- From Grain to Glass: Building the Perfect Complete Brewing System for Your Home

TAGS

- turkey brewery equipment

- small beer brewery equipment,mini beer brewery equ

- 15 gallon jacketed fermenter

- home brewing distillation equipment

- sovereign stainless steel fermenter

- brewing equipment manufacturers uk,home brewing eq

- craft brewery equipment for sale, craft beer equip

- complete brewery for sale

- automatically brew equipment,50L Brewing equipment

- Nano brewery equipment, brewing systems manufactur

- beer brewing equipment

- dry hops addition

- hop additive gun

- hops addition gun

- pilot brewing system

- Microbrewery machine

- mixing tank manufacturers

- Craft beer making equipment for Malaysia

- CIP system

- professional Cleaning in place equipment

FEATURED PRODUCTS

4000L Five vessels turnkey beer brewery

Five vessels craft beer brewhouse system suppliers,Double mash tun+double kettle tun,4000L beer brewhouse with the beer ...

More >>

Turnkey brewing equipment supply near me

Turnkey brewing equipment supply-WEMAC can supply turnkey brewing equipment system.We are one of the most excellent turn...

More >>294.jpg)

All in one brewing system Australia

WEMAC beer equipment manufacturer is a well-known all in one brewing system, with more than 60 years of experience in th...

More >>

10HL 1000L Romania turnkey beer brewery equipment ZXF

1000L electric steam heating beer brewing brewhouse,sell well in Romania.Personalized customization, a variety of heatin...

More >>

Stainless steel boiling tank beer brewing brewery turnkey system supplier ZXF

All size brewery for sale,WEMAC Provide turnkey service for beer brewing system,Professional brewers and technical engin...

More >>

WEMAC 3000L Turnkey beer brewing brewery foul vessels brewhouse manufacturer ZXF

WEMAC specializes in undertaking large, medium and small beer brewing turnkey projects, the quality of WEMAC meets the G...

More >>

Modern beer making brewery turnkey brewhouse system made of high quality stainless steel ZXF

WEMAC provides a turnkey system for a modern beer brewing factory. From the storage and crushing of raw materials and ma...

More >>

100L 300L 500L Electric Beer plant Turnkey Brewing Systems hot sale in Germany ZXF

Grain Handling

Heating System - Electric, Steam, or Direct Fire

Brew House Tanks

Brew House Controls

Pumps

Glycol &...